ITM Uses 3D Printing to Improve Wireless Torque Measurement Designs

One of the ways ITM sets itself apart is that our engineers don’t flinch when it comes to finding creative ways to make tough measurements.

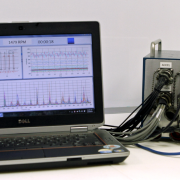

For example, as you can see in this video, we have begun using our in-house 3D printer to customize plastic collars — embedded with sensors and transmitters — which allow us to wirelessly measure torque on rotating machinery.

In this example, we’re recording a signal as the drill bit enters the wood, but the same solution allows us to model and print a larger fixture to measure the stresses on an industrial drive shaft or other piece of rotating equipment.

Where once we might have turned to an area machine shop to mill a similar type collar, we can now model an even more precise tool and print it out overnight — saving valuable time and at a fraction of the cost.

3D Printing is just one more example of how ITM uses cutting-edge tools and new technology to solve problems.

— ITM President Tim Carlier