PRODUCT DETAILS

The Sootblower Fouling Detection (SFD) System is an ITM proprietary technology for the measurement of fouling along the path of a sootblower in recovery and utility boilers.

In a typical boiler, fuel is burned inside the furnace, creating hot gas which heats water in the steam-generating tubes. In the case where the fuel is coal or black liquor, the flue gas often contains a significant amount of carry-over, which collects on the boiler tubes causing buildup. This buildup, also known as fouling, decreases the efficiency of the heat being transferred to generate steam while also increasing the risk of plugging the boiler and taking it offline altogether.

Our SFD system has two primary purposes. One is to help understand where fouling is occurring in order to optimize sootblowing. The other is to provide real-time data for control systems which will allow for targeted sootblowing. Both of these will result in immediate savings in steam consumption, prevention of tube erosion in areas with little to no buildup and increased boiler efficiency in areas with significant buildup.

A secondary benefit of the SFD is sootblower condition monitoring which helps answer the following questions: What’s the condition of the SB motor and gearbox? Is the poppet valve stuck open? Is the track damaged? Is the sootblower lance bent? Is the sootblower stuck in the boiler? What condition is the sootblower packing? Are there any steam leaks on or near the sootblower?

With steam costs reaching an estimated $5,600 a day — or roughly $2 million a year — to power sootblowing operations in a single recovery boiler, imagine the savings plant operators could achieve by optimizing sootblowing.

The key to sootblowing efficiency is knowing where to clean and when. If your plant utilizes a utility or recovery boiler, do you know where the soot buildup is located in that boiler, or are you cleaning blind? Our solution greatly increases sootblowing efficiency and decreases unplanned outages — both of which will result in significant annual savings.

SYSTEM BENEFITS

- Identifies Fouling/Slagging along the Path of the Sootblower

- Saves Steam Consumption

- Reduces Boiler Tube Erosion

- Increases Boiler Efficiency

- Identifies Dangerous Conditions

- Identifies Sootblower Mechanical Faults

- Identifies Steam Leaks

SYSTEM COMPONENTS

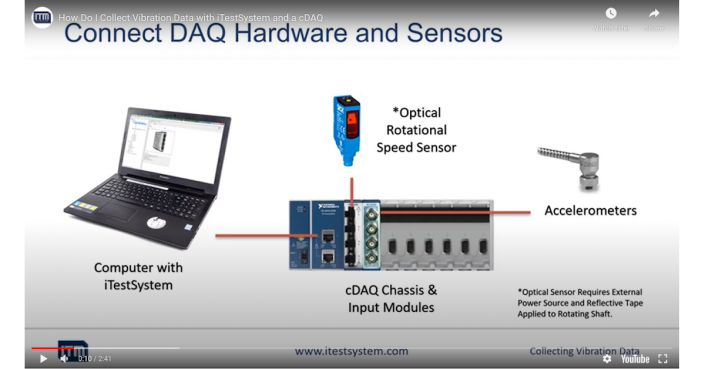

- Stainless steel NEMA4X enclosure

- Industrial real-time Compact RIO controller

- Industrial sensors

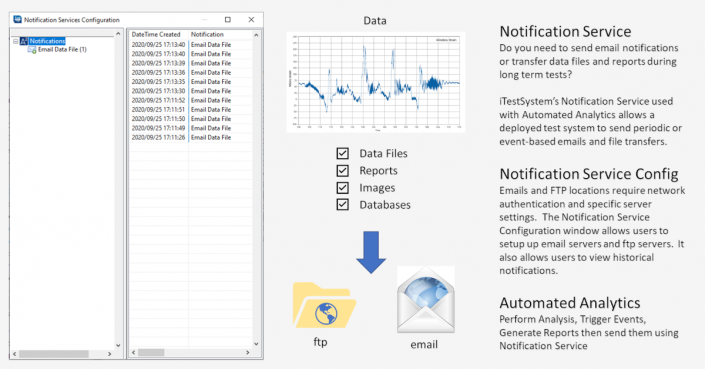

- Real Time data processing and analysis software

- DCS and/or PI System integration via industry standard interfaces

- Detailed Installation Instructions

Recent News

ITM presented its patented Sootblower Fouling Detection (SFD) technology at the Spring 2019 Black Liquor Recovery Boiler Advisory Committee (BLRBAC) meeting in Atlanta, GA on Wednesday, April 10, 2019.

During this presentation, Ryan Welker and Tim Carlier discussed the SFD technology and outlined the benefits it provides to boiler operations.

Sootblower Fouling Detection (SFD) Session HandoutRelated Links Power Magazine Article - Increase the IQ of Your Intelligent Sootblowing

Case Study - Bringing Your “Blind” Sootblowing Process Into the Light